C-Dub Tech

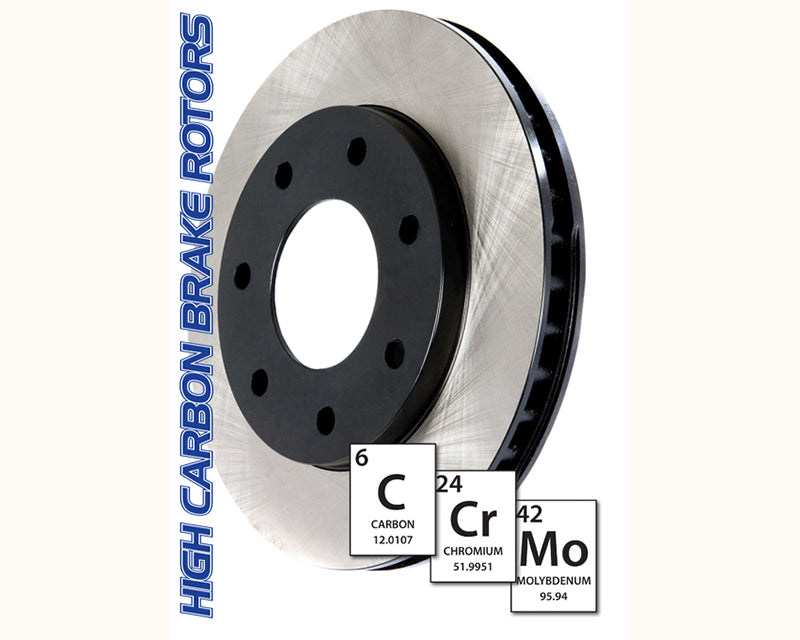

Centric Premium High Carbon Alloy Rotor Rear Dodge Challenger 2008

Centric Premium High Carbon Alloy Rotor Rear Dodge Challenger 2008

Couldn't load pickup availability

Centric parts High Carbon Alloy Brake Rotors feature a double disc ground finish which virtually eliminates run out and any disc thickness variation issues. Double disc grinding also produces a non-directional finish for improved rotor and pad break-in. The surface Roughness production standard for Centric High Carbon Brake Rotors: RMS=64.3 or Ra=1.6 micro-meters (63 micro-inches).

Centric Parts High Carbon Alloy Brake Rotors feature our exclusive black E-Coating on all non-friction surfaces. E-Coating is an advanced electro-statically applied finish that has been engineered to withstand 400 hours of salt spray testing without corroding.

Centric Parts High Carbon Alloy Brake Rotors utilize the same symmetric vane molding process used by OE manufacturers. Rotors with symmetric vanes dissipate heat more efficiently and provide better stopping power especially in repeat stop situations.

Centric High Carbon Alloy Brake Rotors are mill balanced to a tolerance of less than 2oz.inch. This additional machining operation reduces feedback associated with rotor vibration and provides a smooth confident application of braking force.

Features:

- Symmetric vane castings for Increased strength and stability

- Black E-Coat anti-corrosive coating protects the cooling vanes and mounting surfaces from rusting prematurely

- Double disc ground friction surface finish

- Mill balancing ensures smooth operation at all speeds

- Images are for representation only. Actual product may vary.